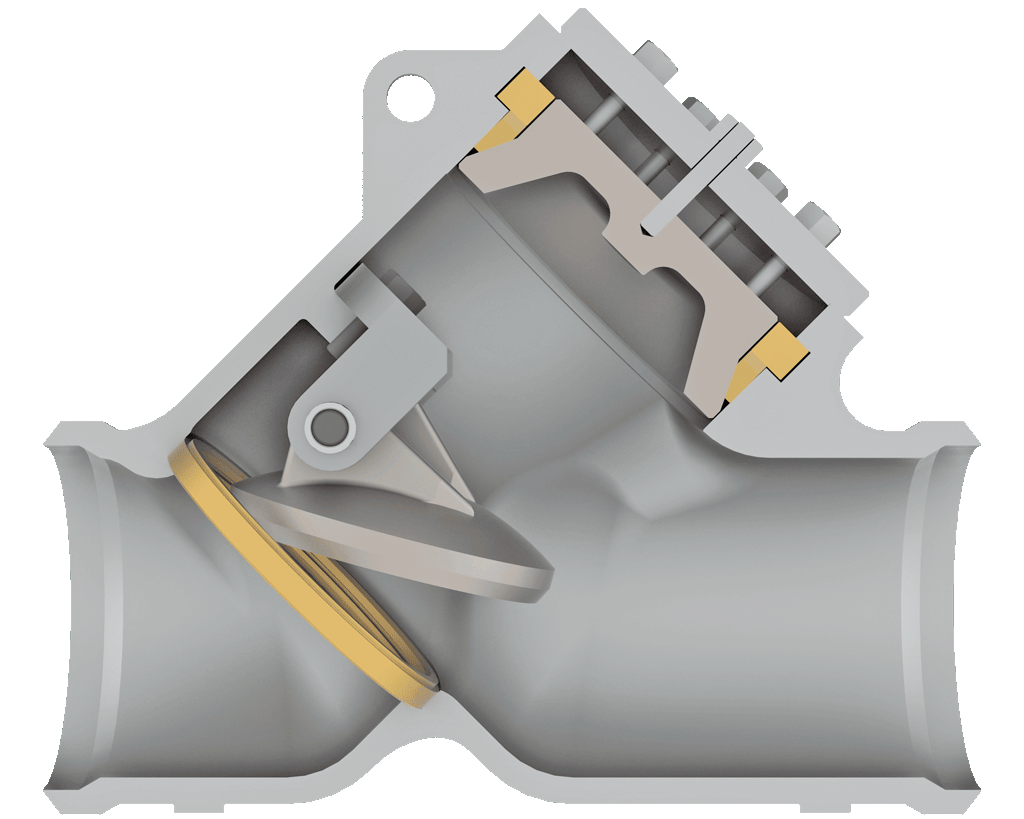

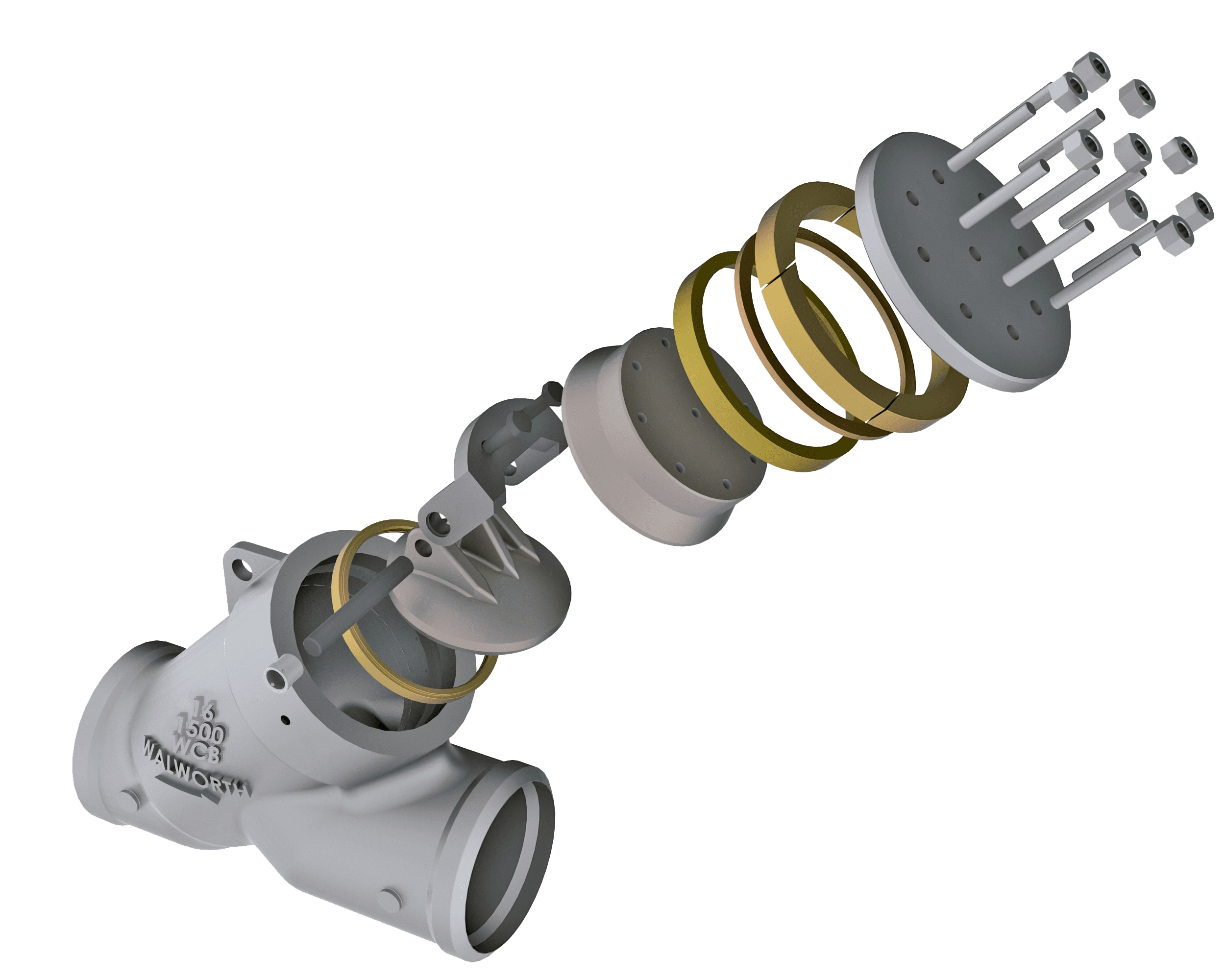

TILTING DISK PRESSURE SEAL CHECK VALVE

- Mainly used in power plants involving fossil fuels, coal, gases, nuclear and thermal power, boilers, steam stations, etc. as valves to avoid backflow. Typically fitted downstream of a pump.

- Designed to leverage the ability to use pipeline fluid pressure to enhance sealing action with a pre-loaded graphite or metal gasket strategically placed between the body and hood.

- Designed in accordance with ASME B16.34.

- ASME Classes 600, 900, 1500, and 2500