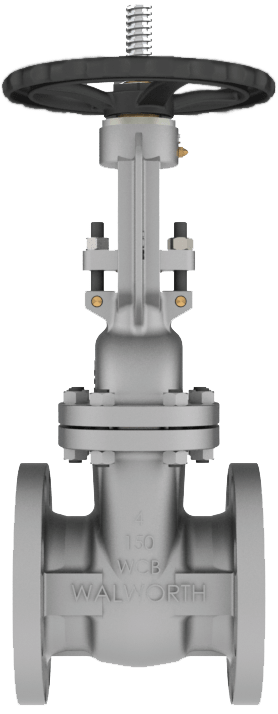

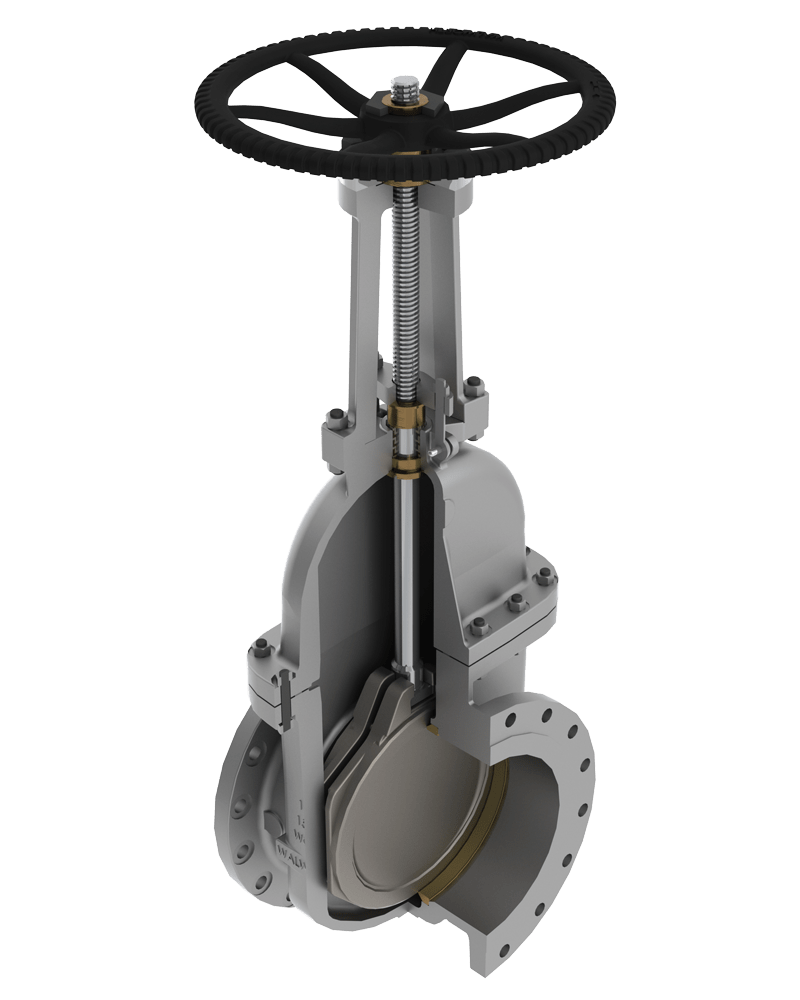

CAST STEEL GATE VALVE

- Suitable for installation in refineries, chemical plants, petrochemical plants, oil industry processes or others where corrosion or erosion occurs, or flow diversion is required.

- Designed in accordance with API-600, ISO-10434 and BS-1414.

- ASME Classes 150, 300, 600, 900, 1500 and 2500