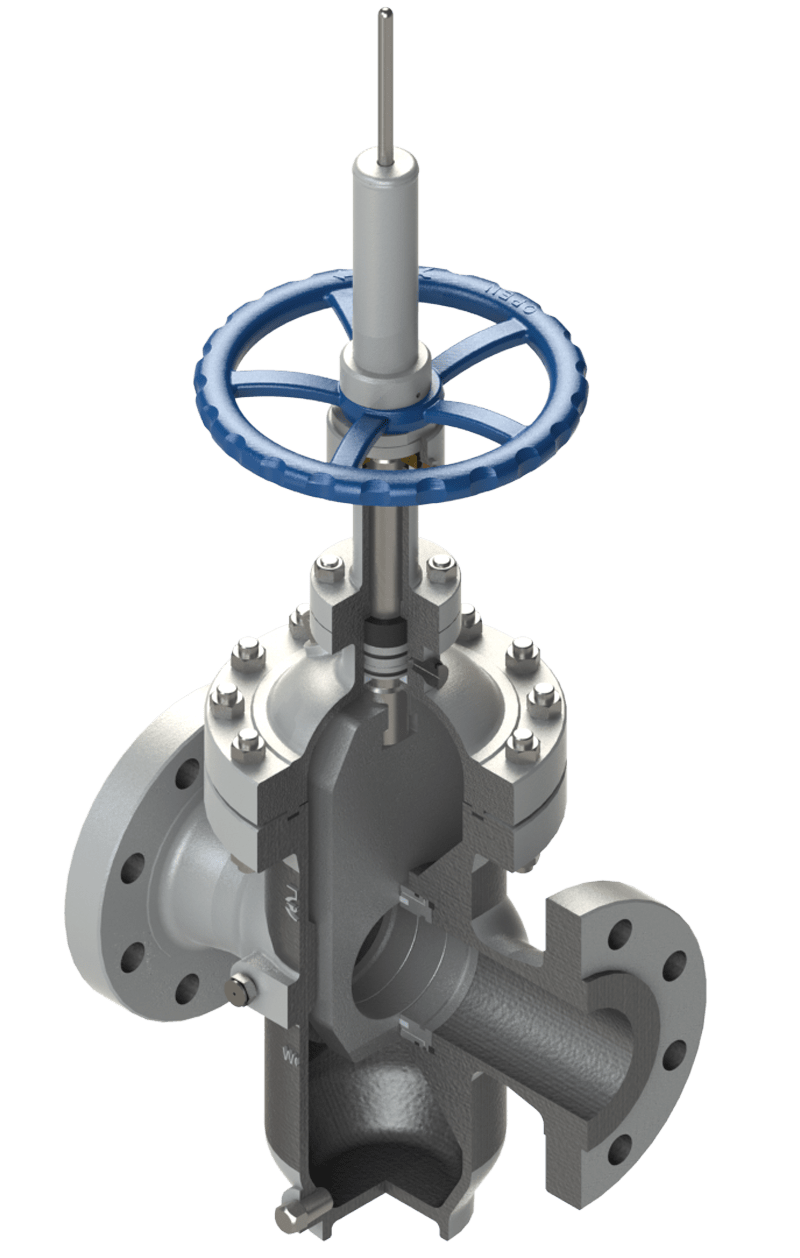

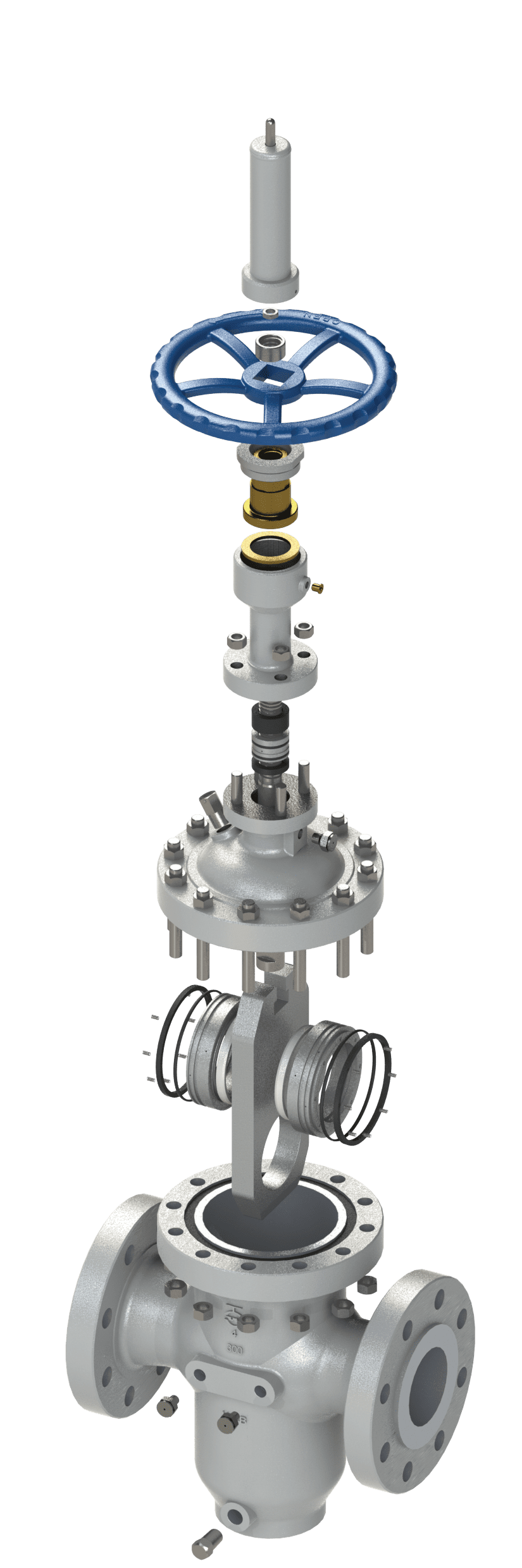

THROUGH CONDUIT SLAB GATE VALVE

- Its main application is in crude oil, gas and oil derivatives transportation, in specific areas such as natural gas, crude oil or refined products transportation in pumping lines, compression and re-injection stations, terminals, pig traps and metering stations.

- Design in accordance with API-6D and ISO-14313.

- Completely continuous flow.

- Also compliant with PEMEX EST-0211/002 requirements.

- ASME Classes 150, 300, 600, 900, 1500 and 2500.