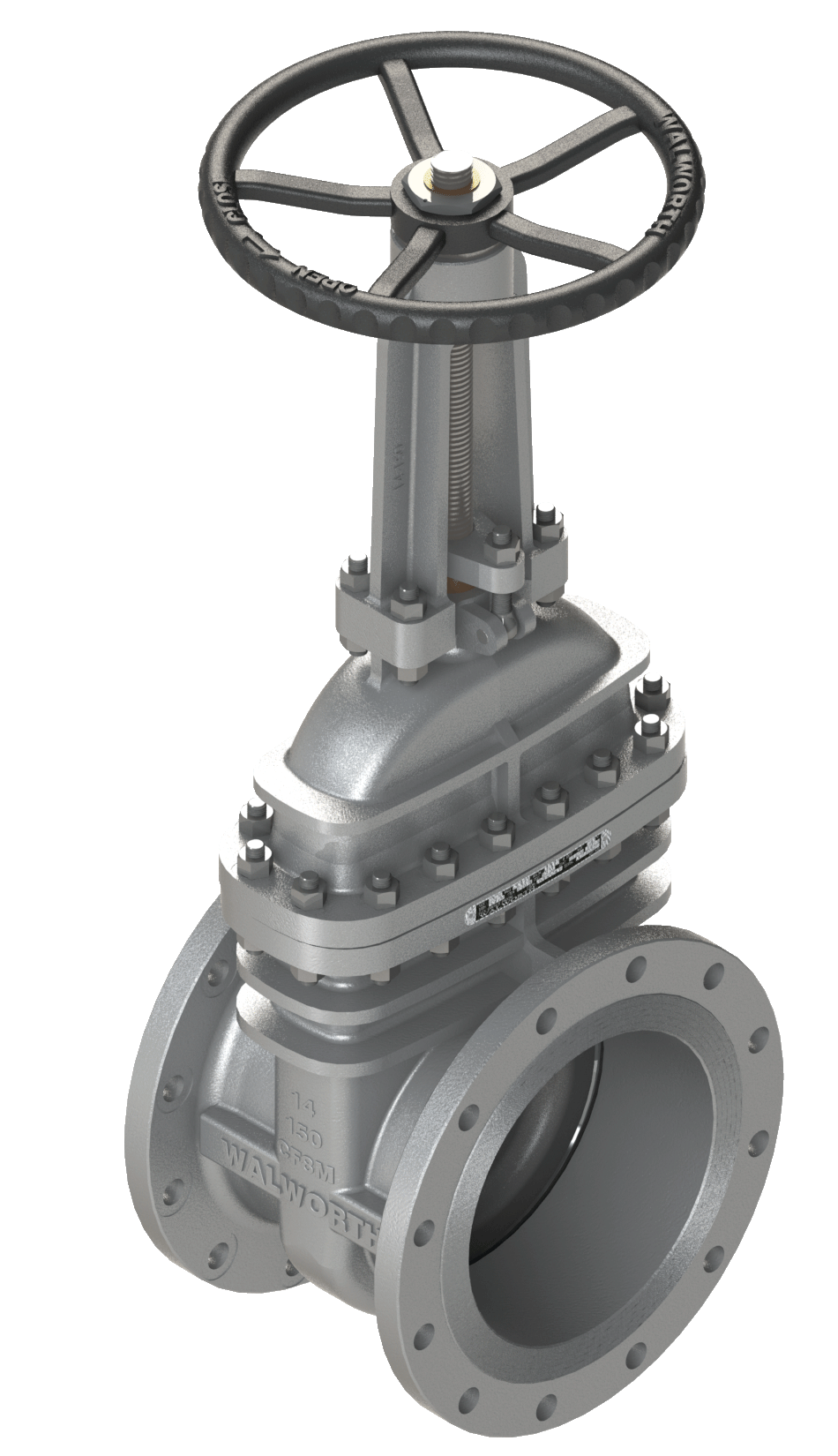

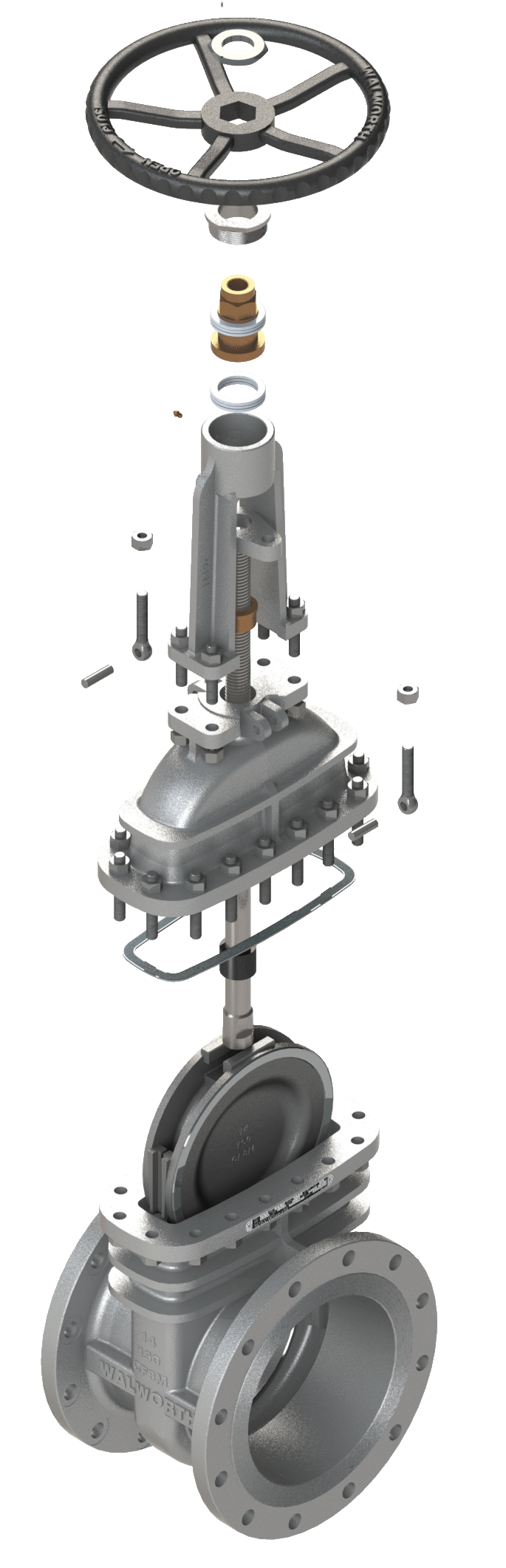

LIGHT DESIGN CAST STEEL GATE VALVE

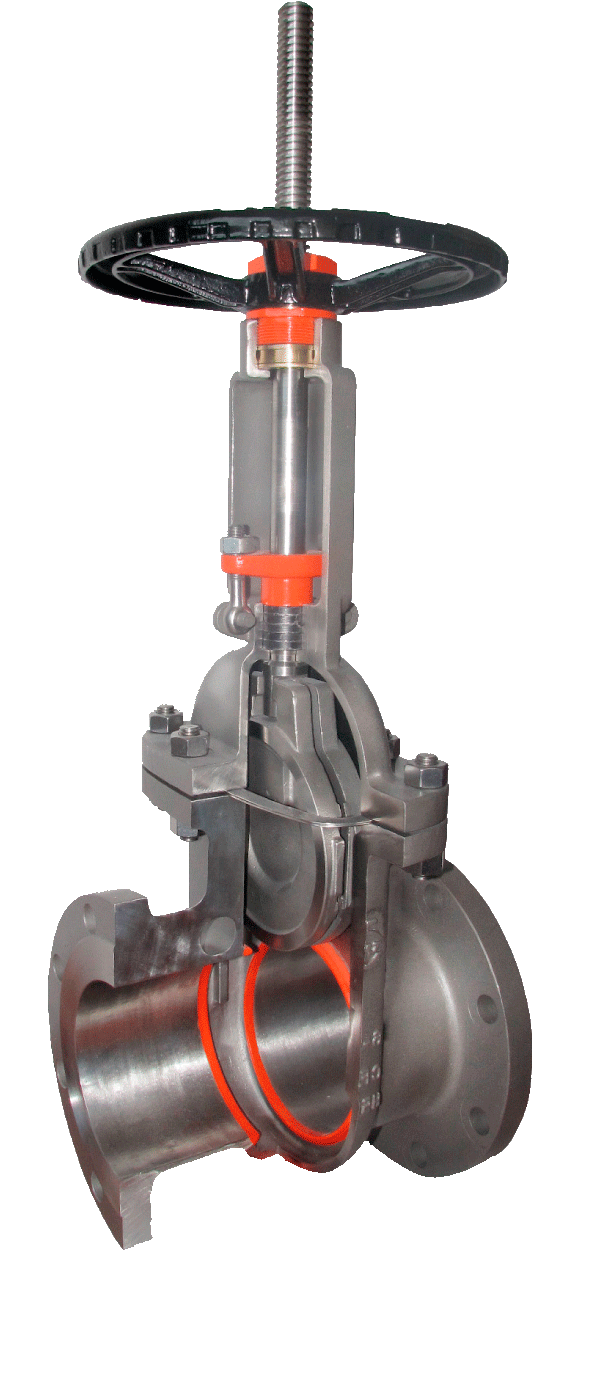

- For installation in industrial plants where corrosion resistance is primarily required for flow diversion.

- Manufactured from stainless steel or nickel alloys (ASME B16.34 groups 2 and 3).

- API-603 compliant design; also ASME B16.34 compliant.

- ASME Classes 150, 300, 600; for classes 900 and 1500 in accordance with ASME B16.34.