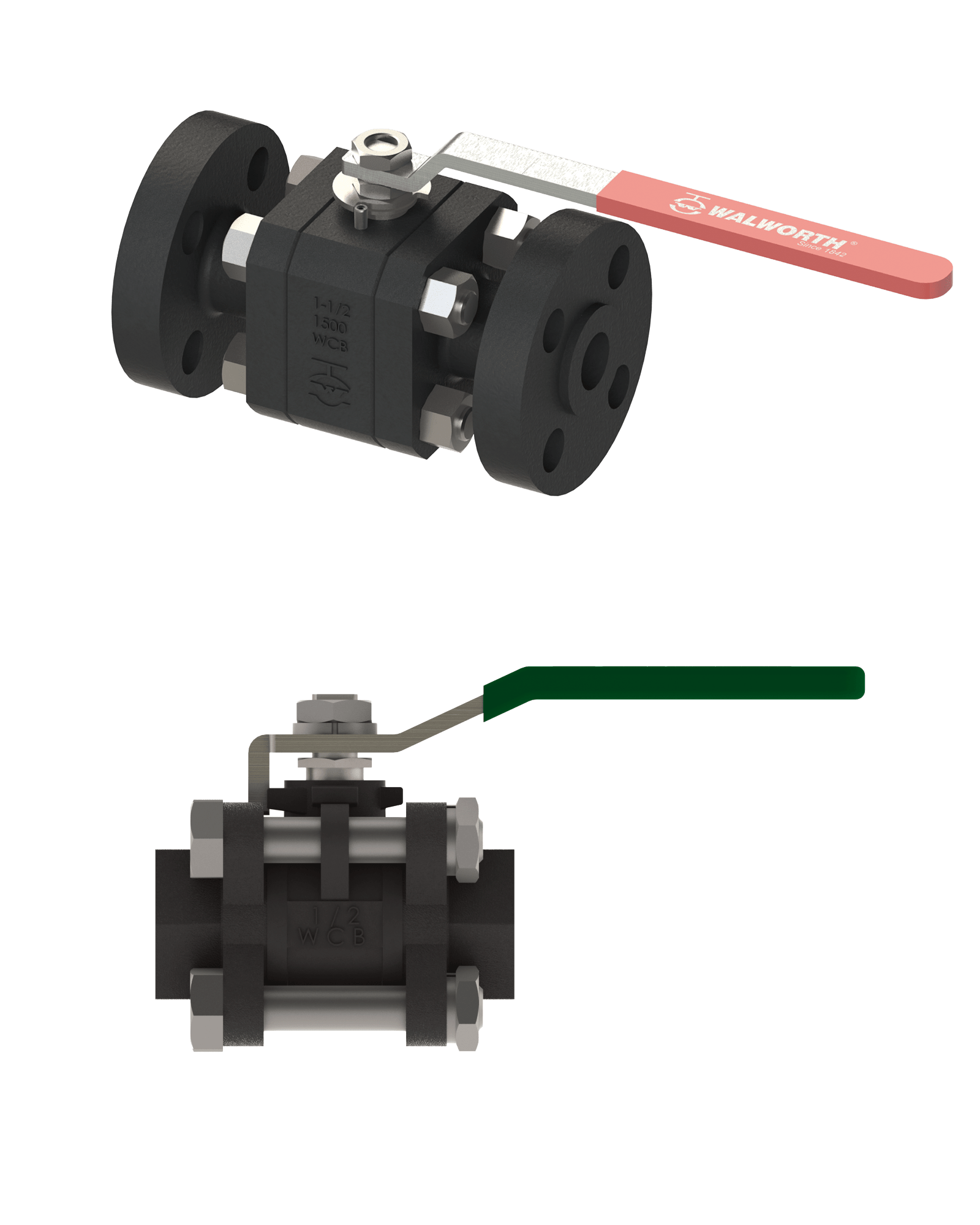

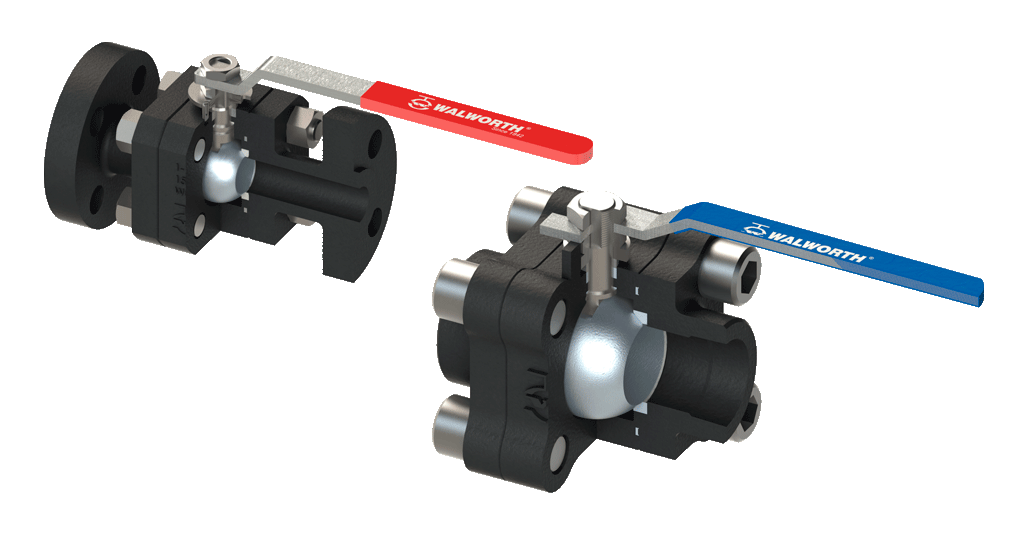

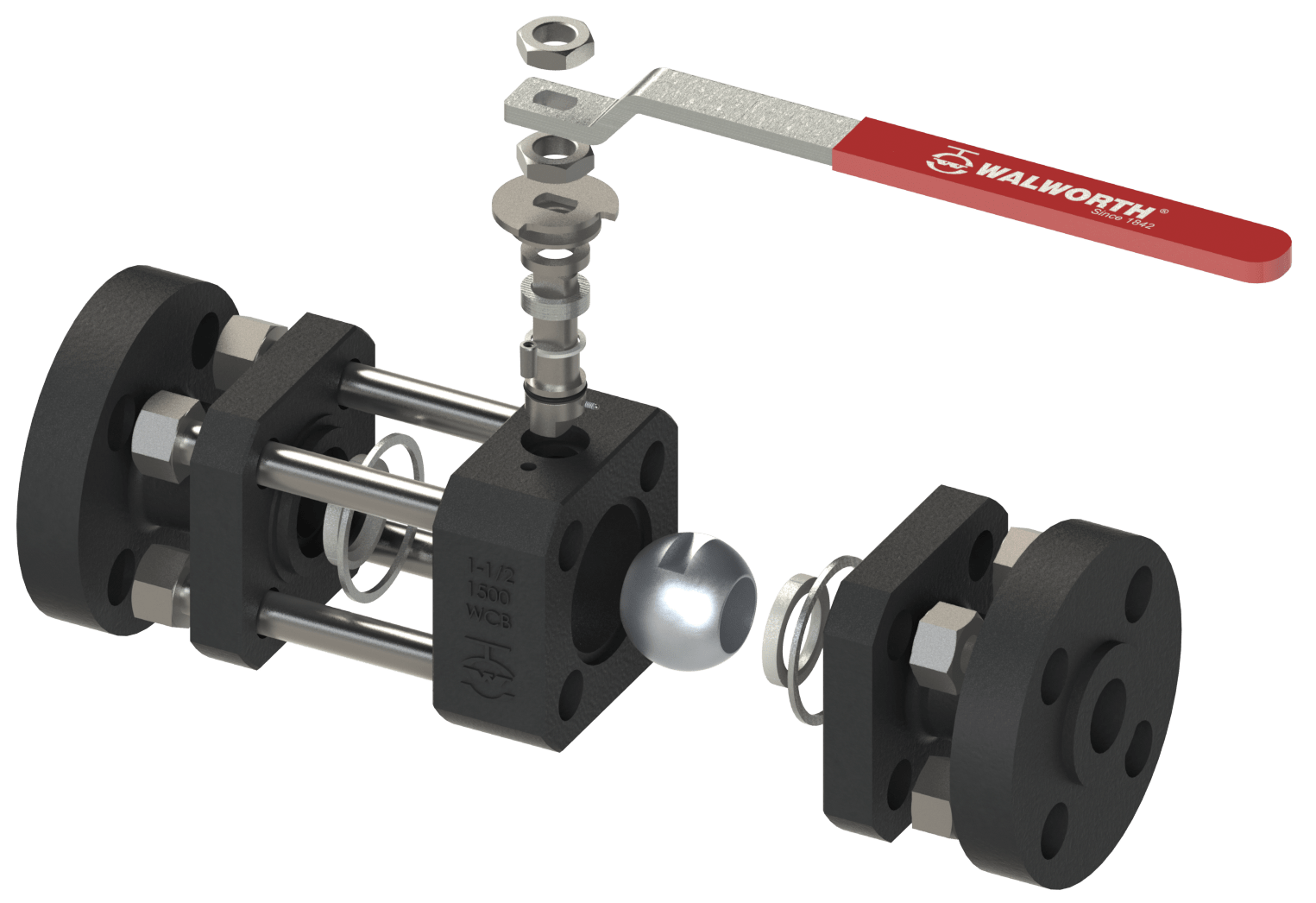

CAST BODY FLOATING BALL VALVE FOR OIL SERVICE.

- For installation on platforms for crude oil exploitation (offshore), transportation of oil, gas and its derivatives (Onshore) as well as in refineries, chemical plants, petrochemical, oil industry processes or others where there is corrosion, erosion, or flow diversion is required.

- API-6D compliant design for installation on platforms (upstream).

API-608 for ground installations (midstream and downstream). Also meets ISO-14313 and BS-5351 criteria. - Flame-retardant design in accordance with API-6FA, API-607 and ISO-10497.

- ASME Classes 800, 1500 and 2500.

- Body with weld box ends (SW), threaded ends (S) or mixed ends (SW / S).