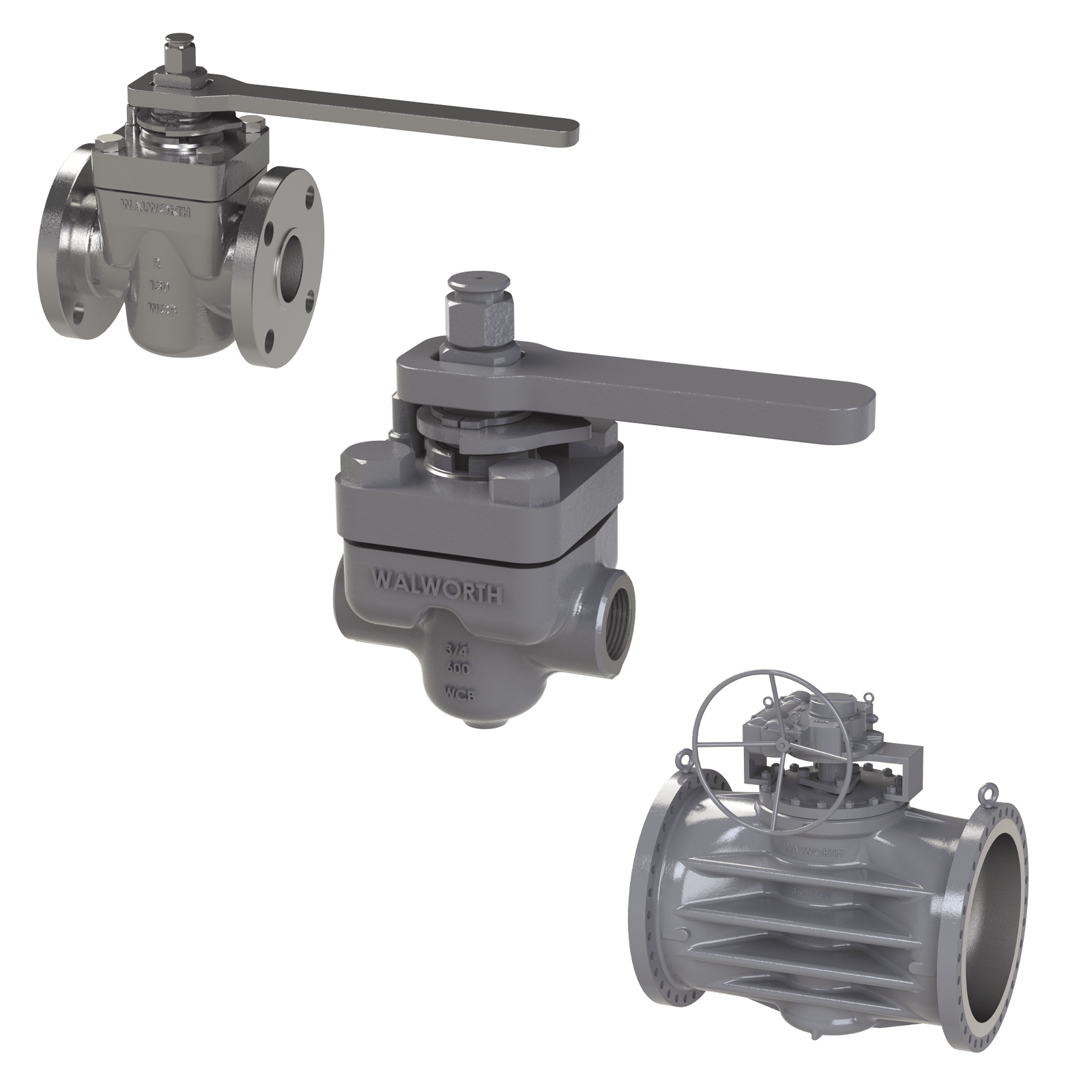

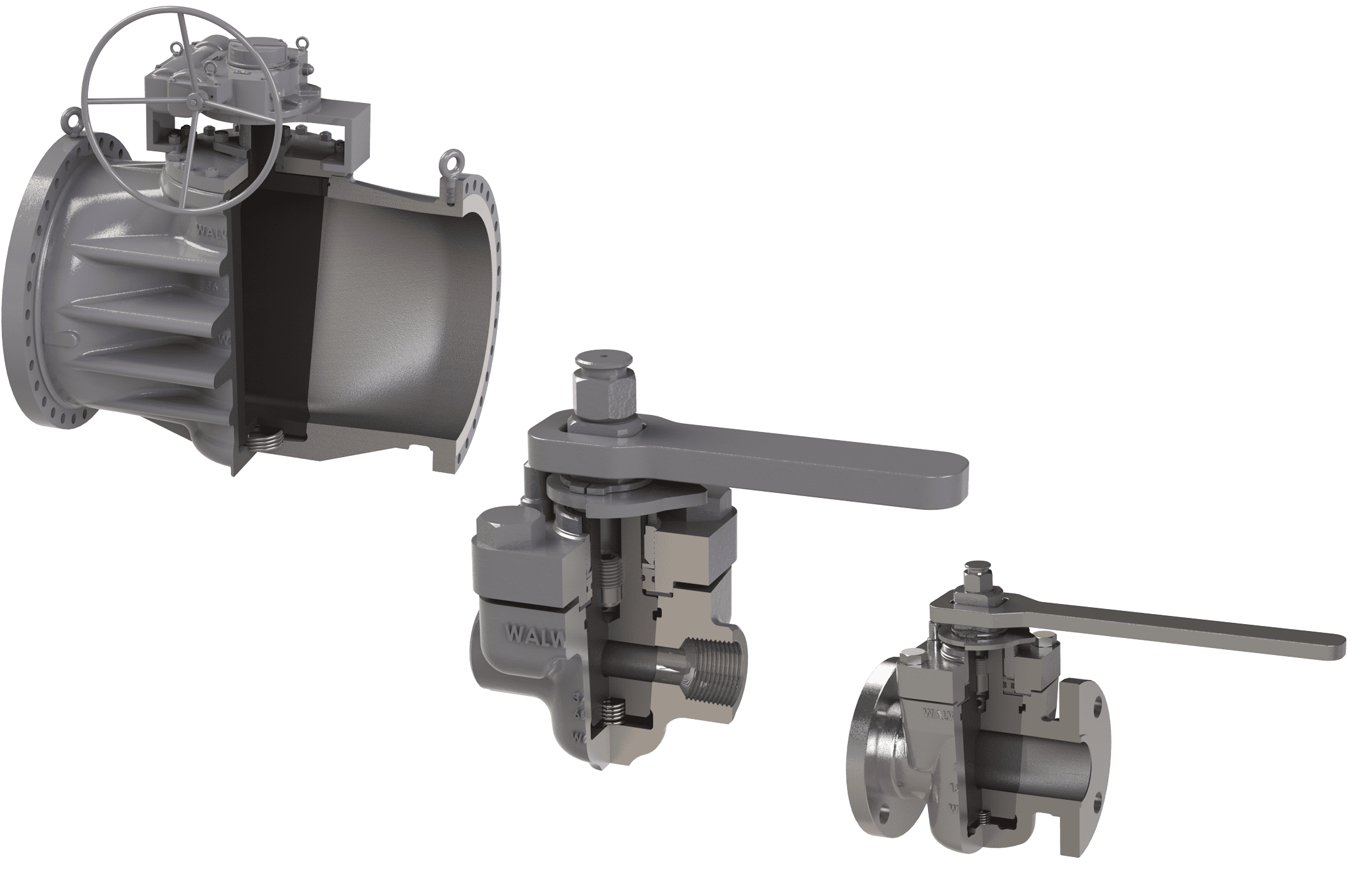

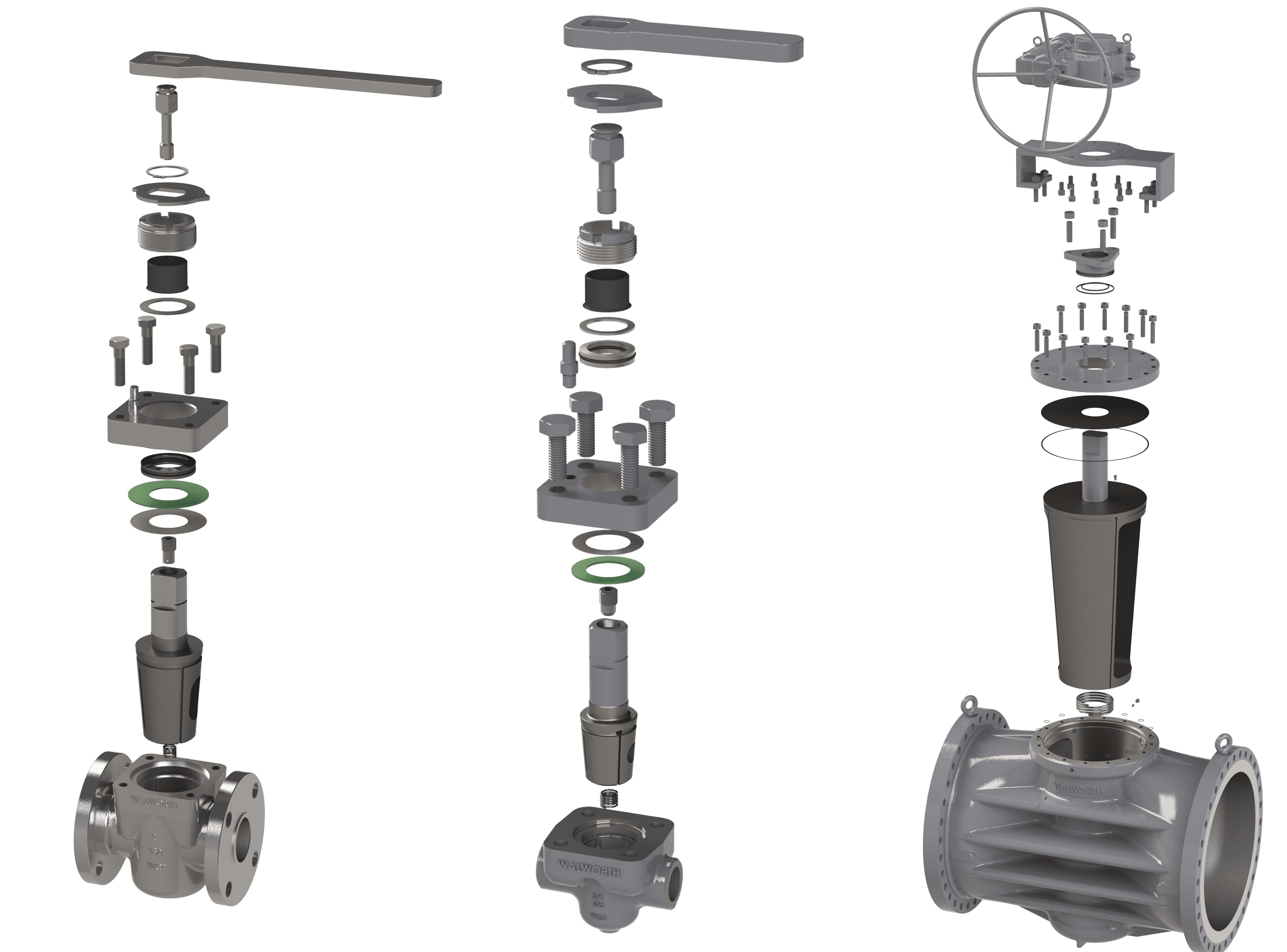

NORMAL PLUG STEEL PLUG VALVE (Top entry).

- Flow divider valve with a fairly uninterrupted steady fluid flow with minimal resistance when the valve is open so it can operate with any type of fluid such as liquid, gas, steam and even those containing solid particles in suspension such as coal particles or other minerals, sludge, drainage water or causing precipitates; however, its use is more common in gas transmission systems and in oilfields.

- API-6D and ISO-14313 compliant design; also meets design requirements of API-599 standard.

- Top entry design is commonly used in less critical services in drive systems.

- -For diameters from NPS 1/2 to NPS 12 in ASME Class 150, 300 and 600.

-For diameters from NPS 14 to NPS 36 in ASME Class 150. - Available on the following models:

Short model: 40 - 60% of port diameter of a full port valve.

Regular model: 60-70% of port diameter of a full port valve.

Ventury model: 40-45% of port diameter of a full port valve.