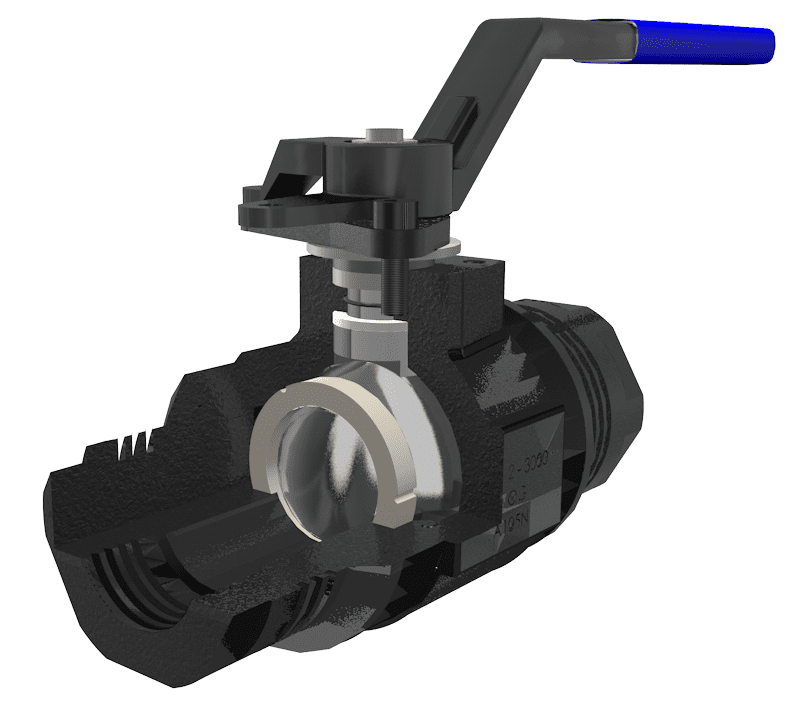

FLOATING BALL VALVES FOR SEVERE USE APPLICATIONS.

- For installation on platforms in critical areas with severe use for crude oil exploitation (offshore), transportation of oil, gas and its derivatives (Onshore) as well as in refineries, chemical plants, petrochemical, oil industry processes or others where there is corrosion, erosion, or flow diversion is required.

- API-608 compliant design; also meets design criteria of ASME B16.34.

- Flame-retardant design in accordance with API-607 and ISO-10497.

- -ASME Classes 600, 800, 900, 1500, and 2500.

-WOG Classes 1000, 2000, 3000, 4000, and 6000 - Bolted body or welded body designs