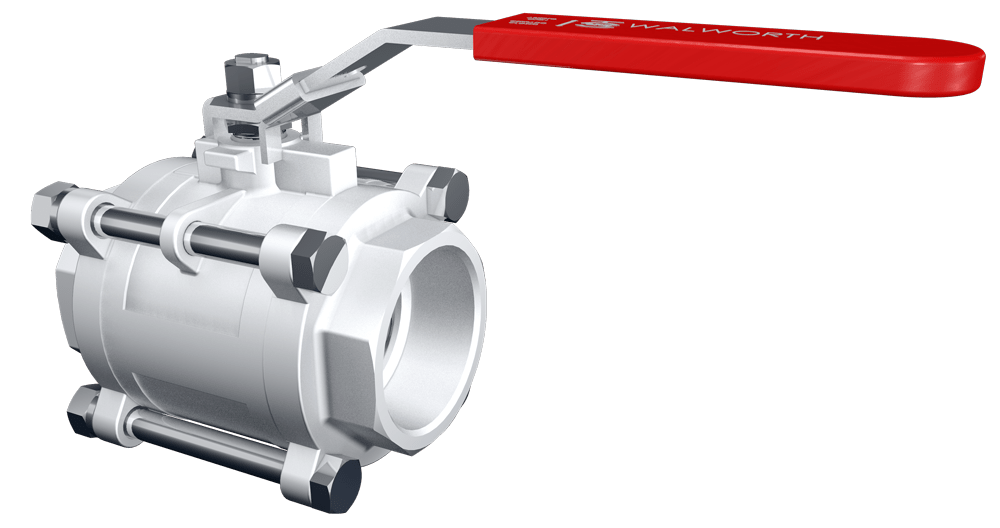

FLOATING BALL VALVES FOR GENERAL SERVICE APPLICATIONS.

- For installation in industries such as construction, sanitary services, civil works services, water and gas pipelines and other services where flow diversion is required.

- Designed in accordance with MSS-SP-110.

- Three-piece body and bolted end design.

- WOG Classes 1000, 2000 and 3000.