SAFETY AND RELIEF VALVE

- Designed to relieve overpressure in a piping system containing compressible or incompressible fluids.

- It is the preferred solution for automatically relieving overpressure in boilers, pressure vessels or other systems when the pressure and / or temperature exceeds the allowable limits.

- Design in accordance with ASME PVC Section VIII Div. 1, as well as ASME B16.34 design requirements.

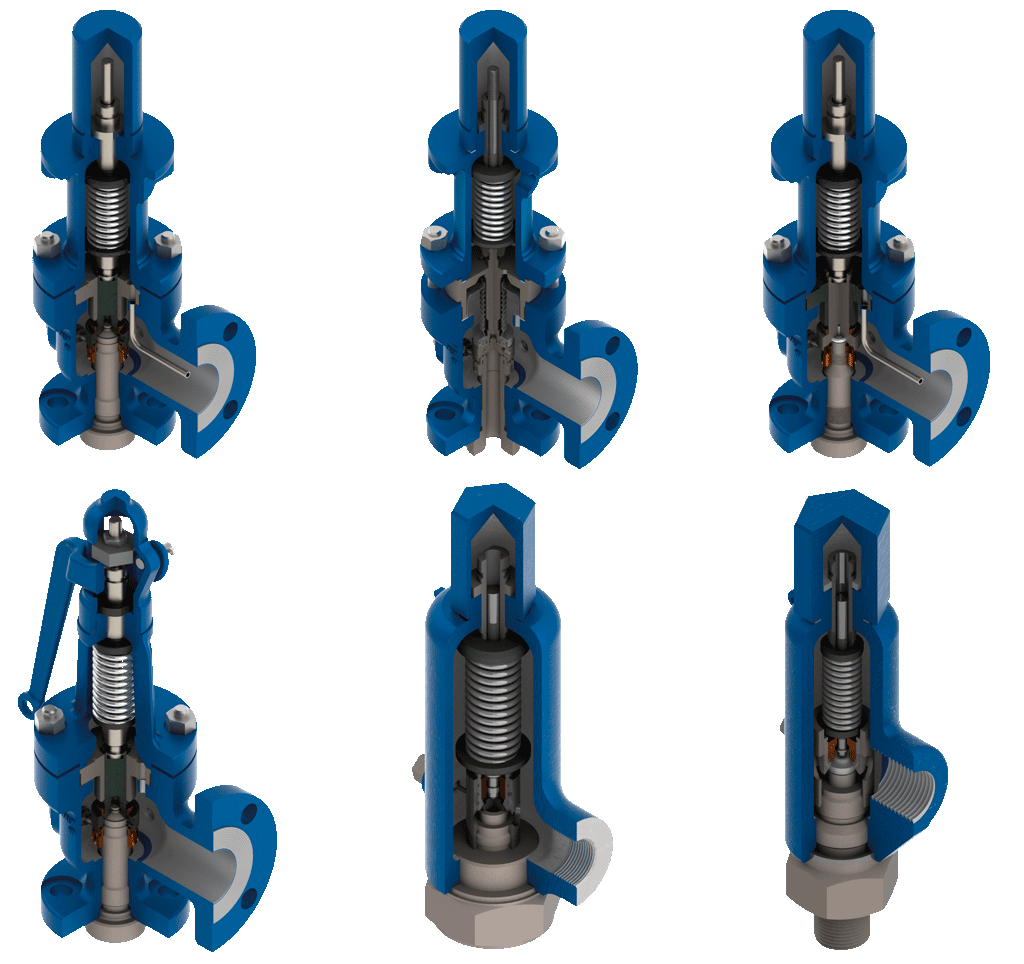

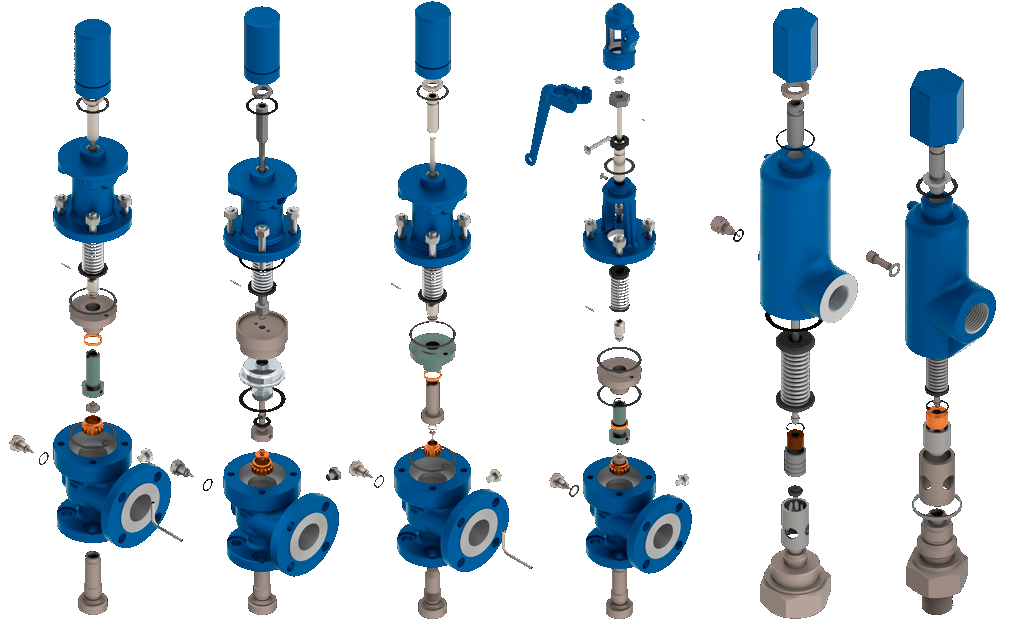

- Conventional style steel safety and relief valves with bellows, soft seat and open hood classes: 150 x 150, 300 x 150, 600 x 150.

- Portable steel safety and relief valve classes: 2000 and 5000.