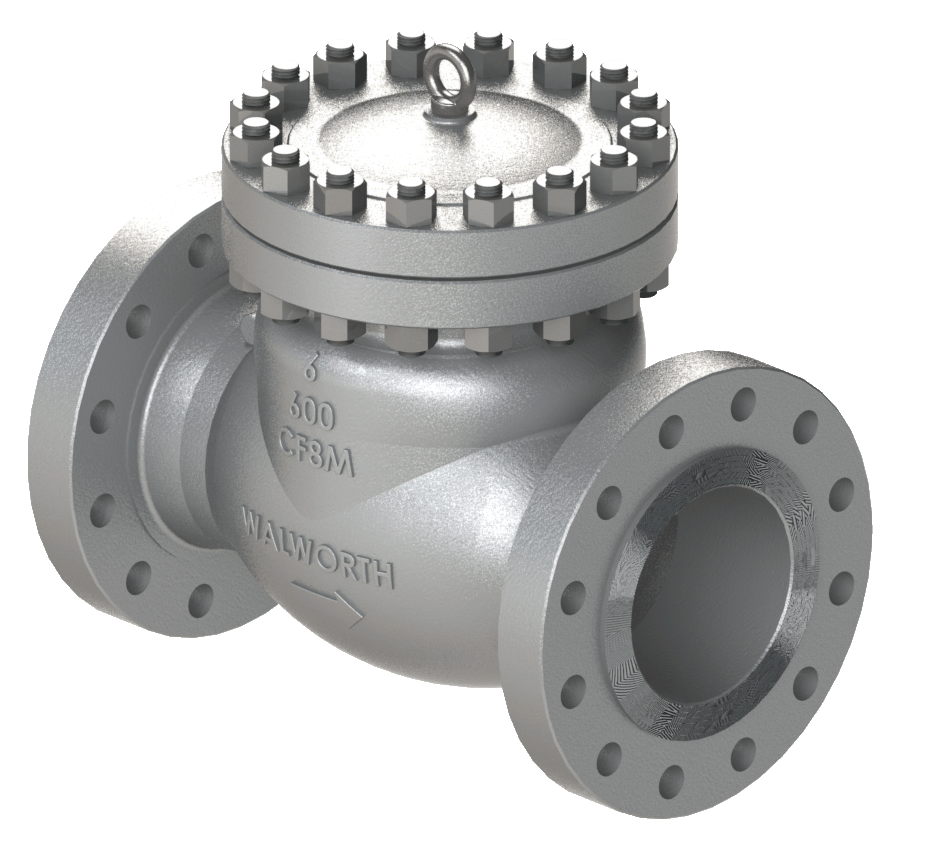

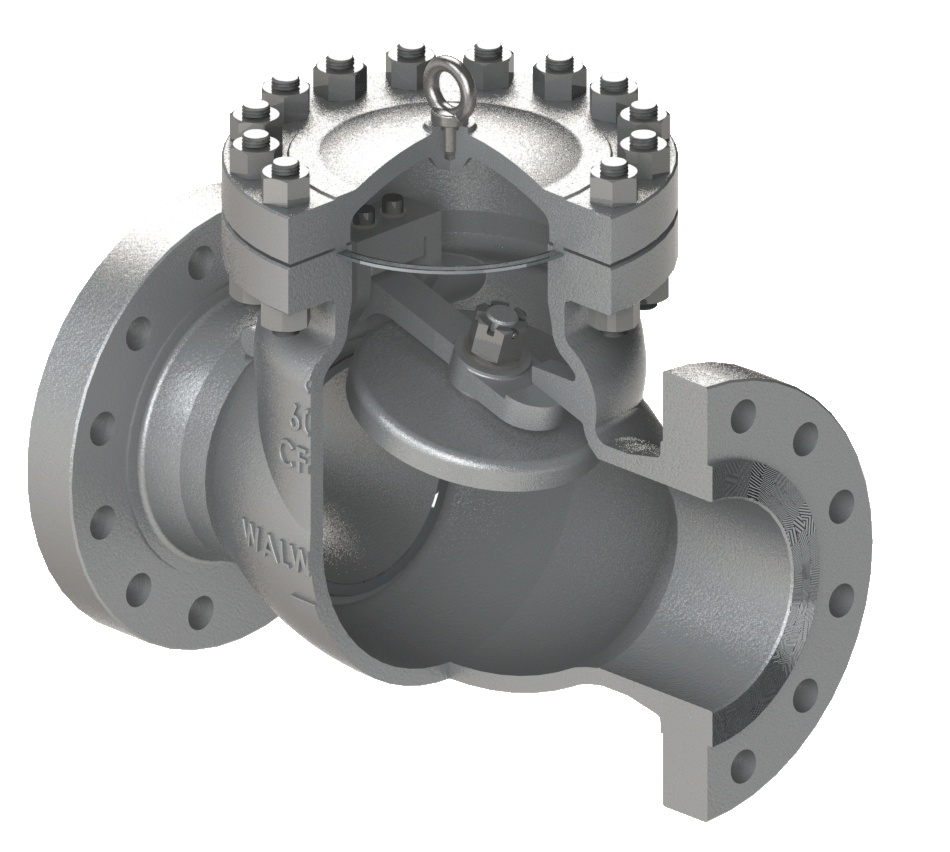

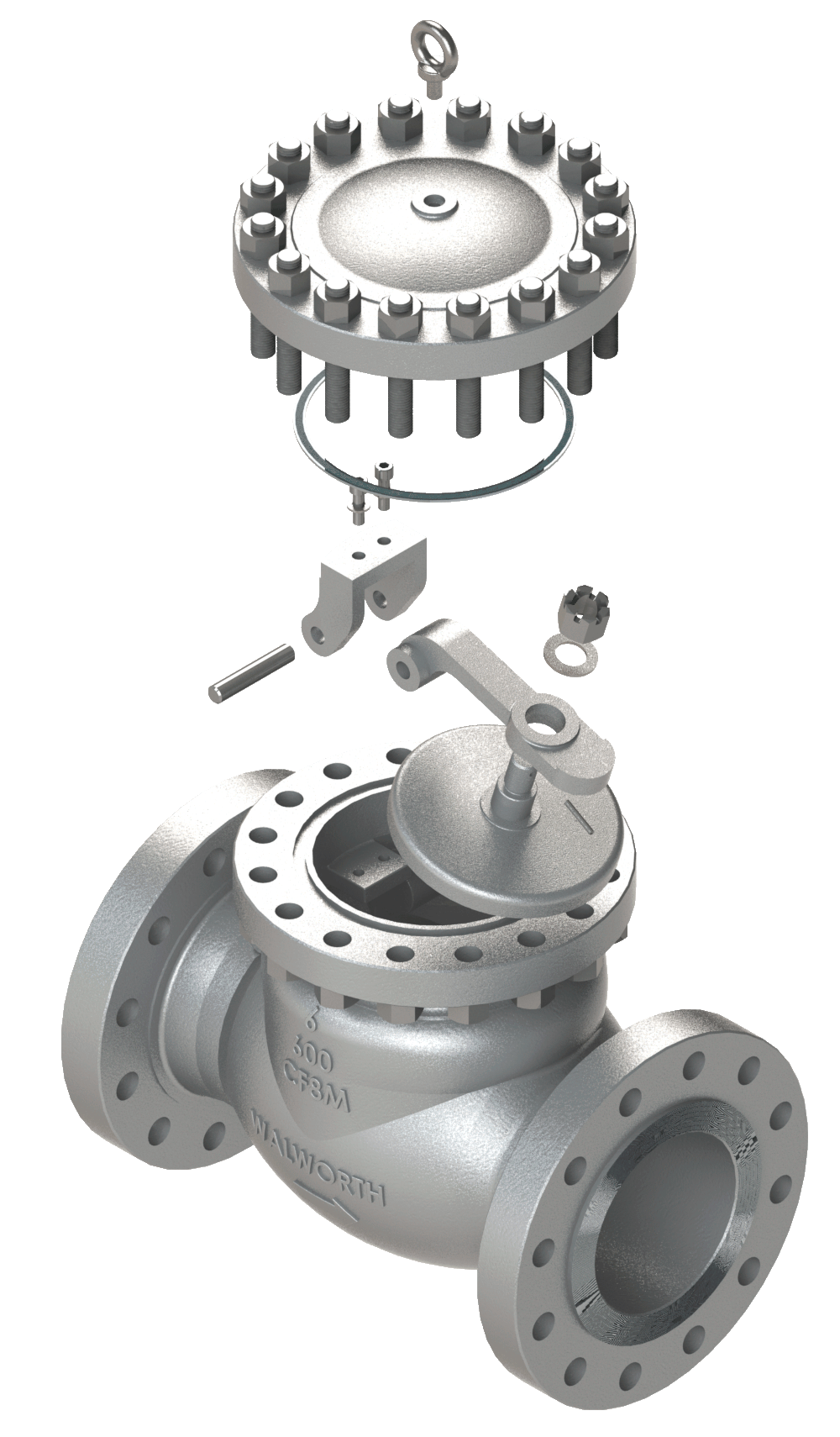

LIGHT DESIGN CAST STEEL SWING CHECK VALVE

- For installation in industrial plants where corrosion resistance is mainly required to avoid backflow.

- Manufactured from stainless steel or nickel alloys (ASME B16.34 groups 2 and 3)

- Designed in accordance with ASME B16.34.

- ASME Classes 150, 300, 600, 900, and 1500.