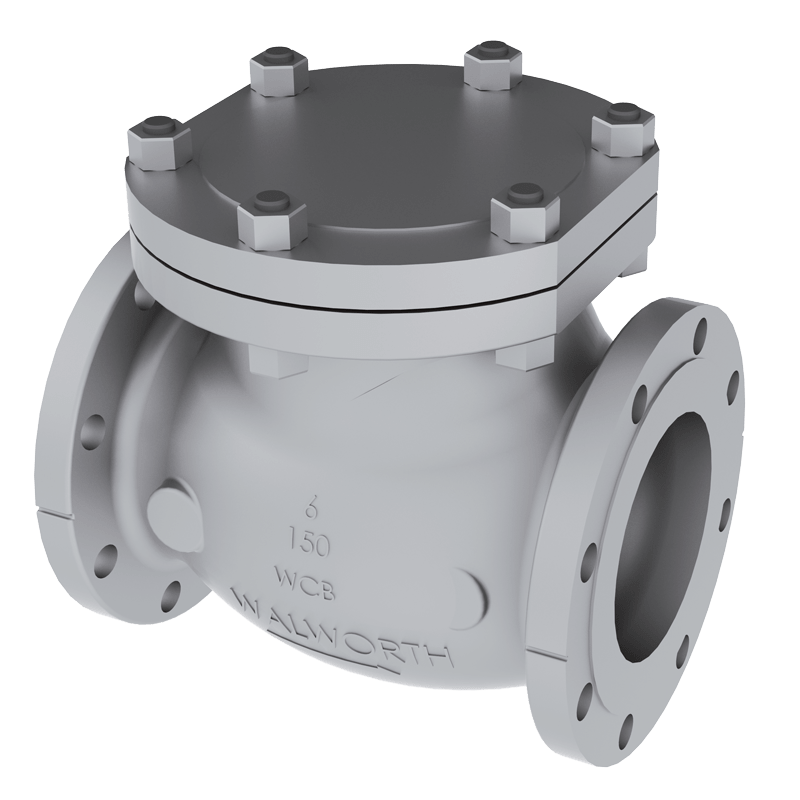

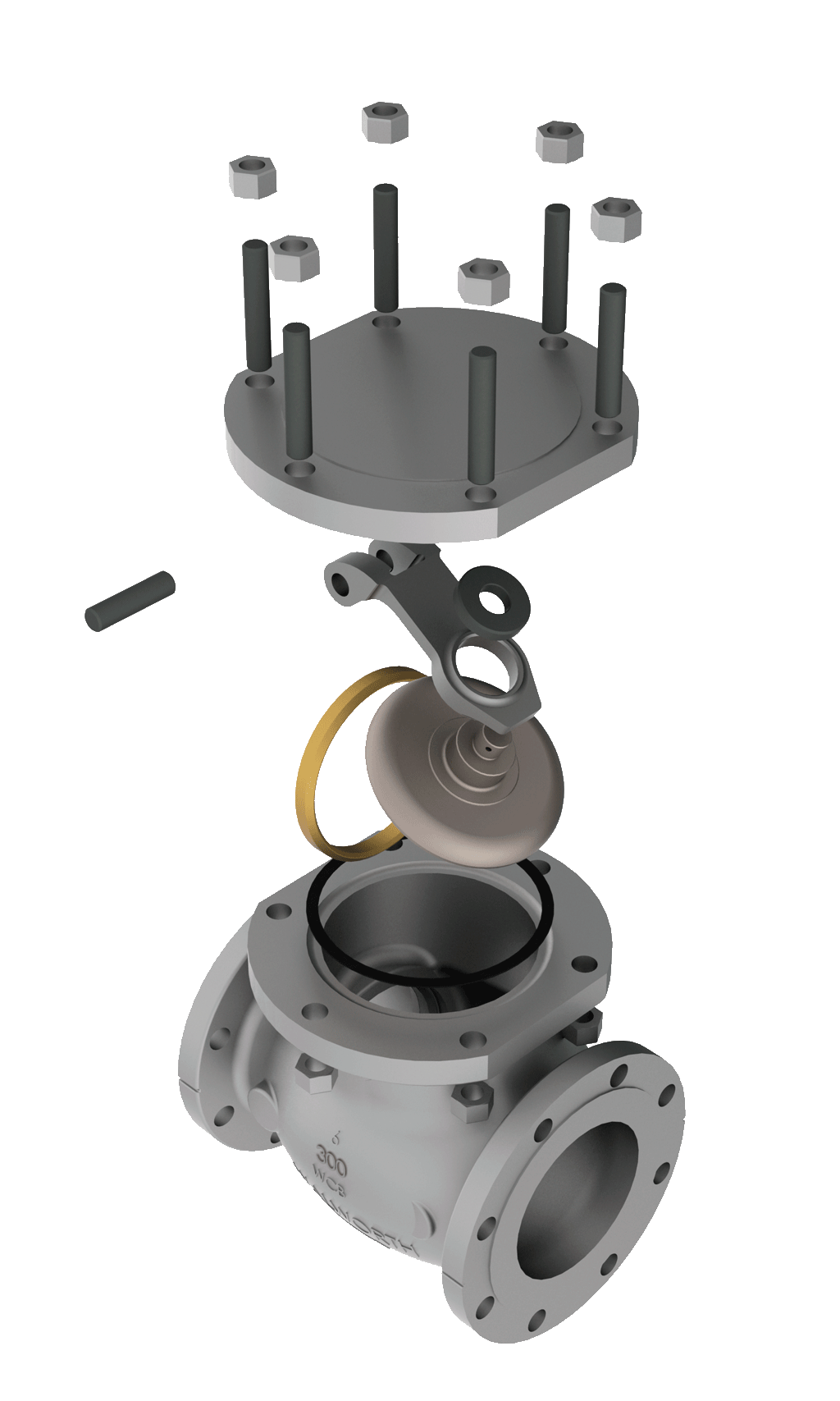

CAST STEEL SWING CHECK VALVE

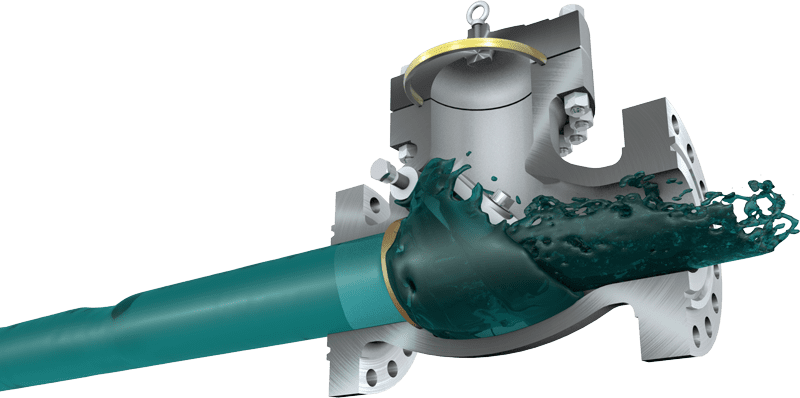

- Suitable for installation in refineries, chemical plants, petrochemical plants, oil industry processes or others with corrosion, erosion or to prevent backflow.

- Designed in accordance with API-594 type B, ISO-15761 and BS-1868.

- ASME Classes 150, 300, 600, 900, 1500 and 2500