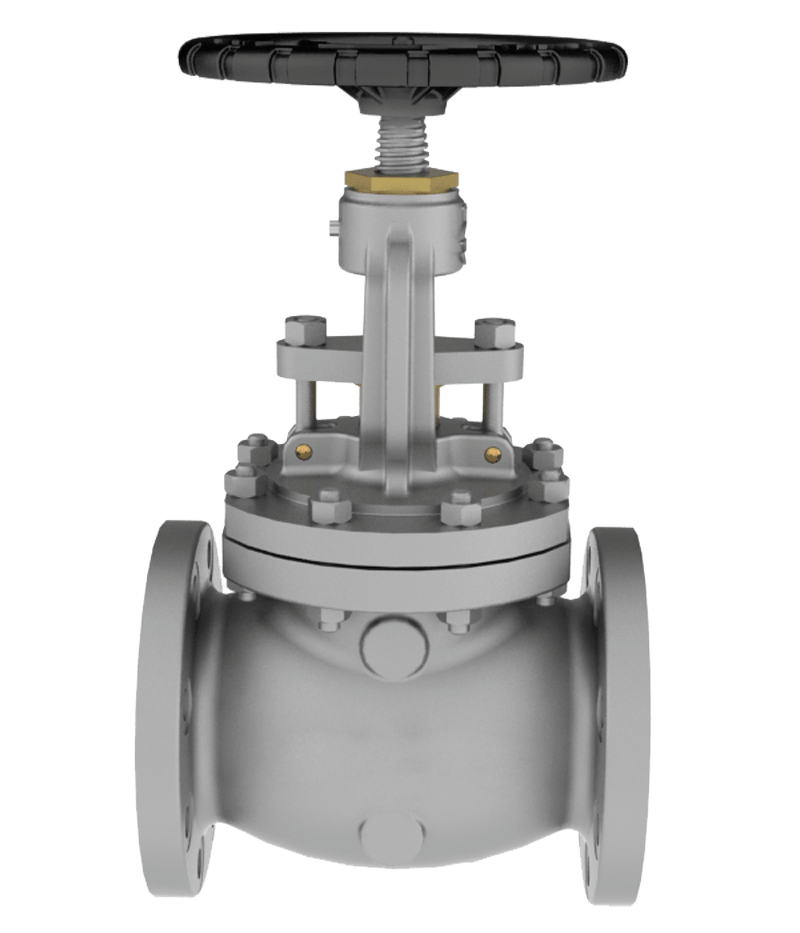

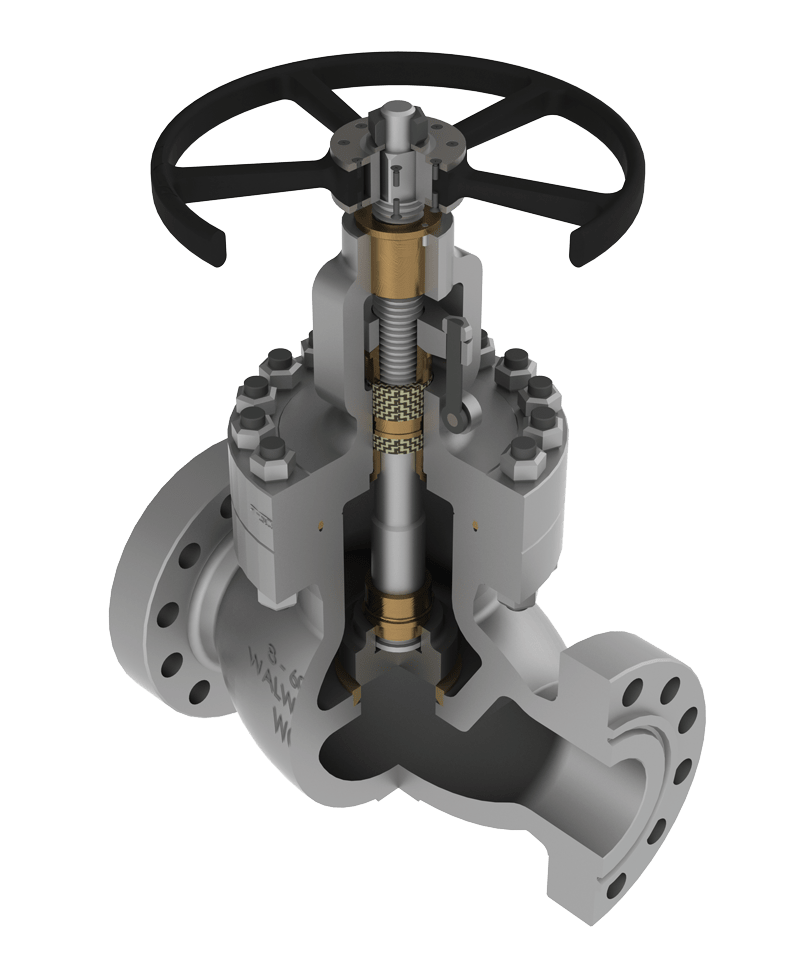

CAST STEEL GLOBE VALVE

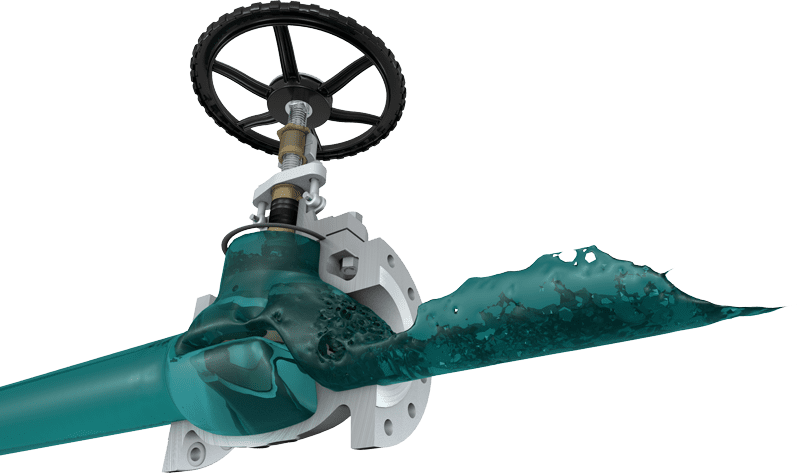

- Suitable for installation in refineries, chemical plants, petrochemical plants, oil industry processes or others where there is corrosion, erosion or volumetric flow control is required.

- Designed in accordance with API-623, ISO-15761 and BS-1873.

- ASME Classes 150, 300, 600, 900, 1500 and 2500