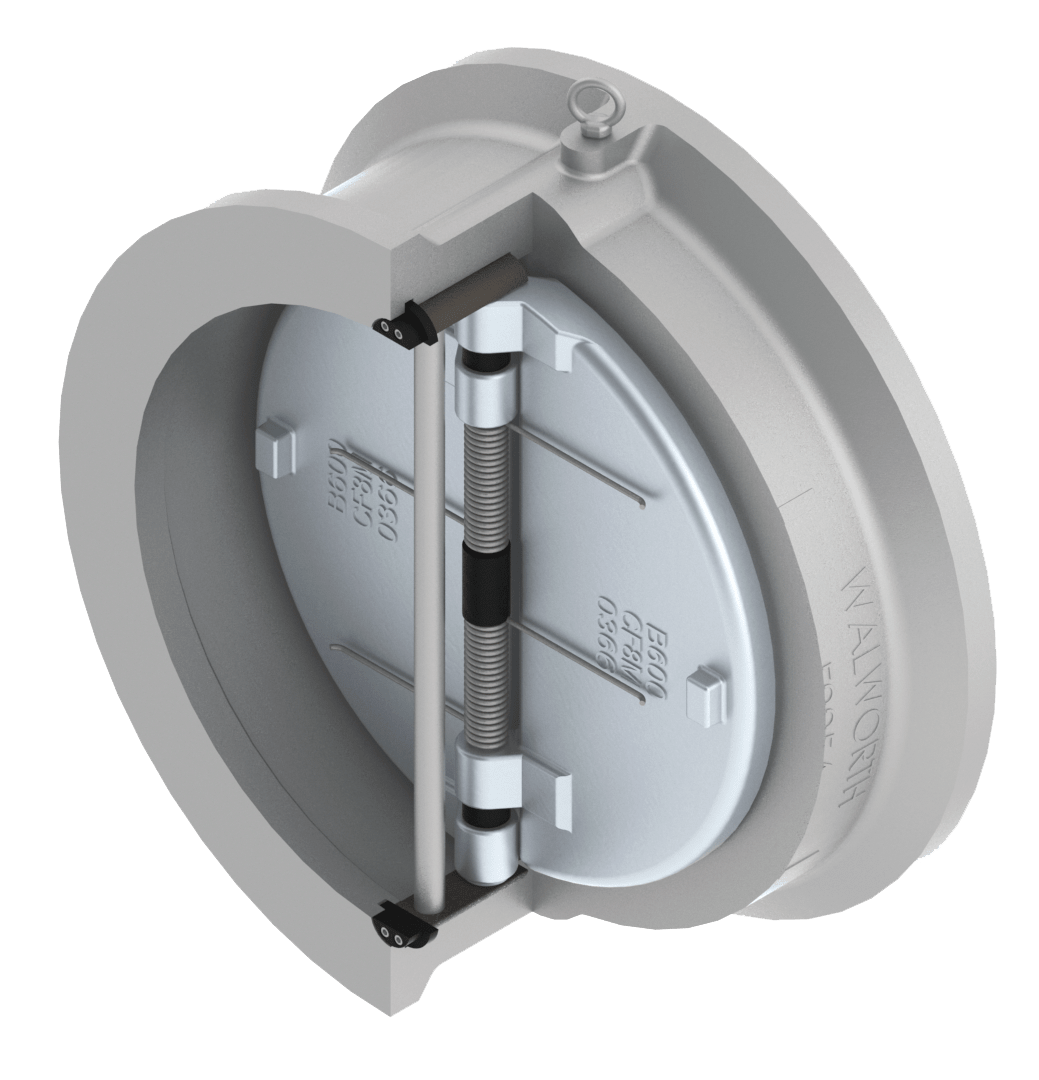

CAST STEEL DUAL DISC CHECK VALVE WAFER STYLE (Dual Plate)

- This is the preferred valve for installations where weight reduction of system structures is required or where spacing problems occur in comparison to other similar type valves.

- They are also used to prevent backflow.

- Widely used on offshore platforms for the extraction of crude oil, gas and their derivatives.

- Design in accordance with API-594 Type A.

- ASME Classes 150, 300, 600, 900, 1500 and 2500.