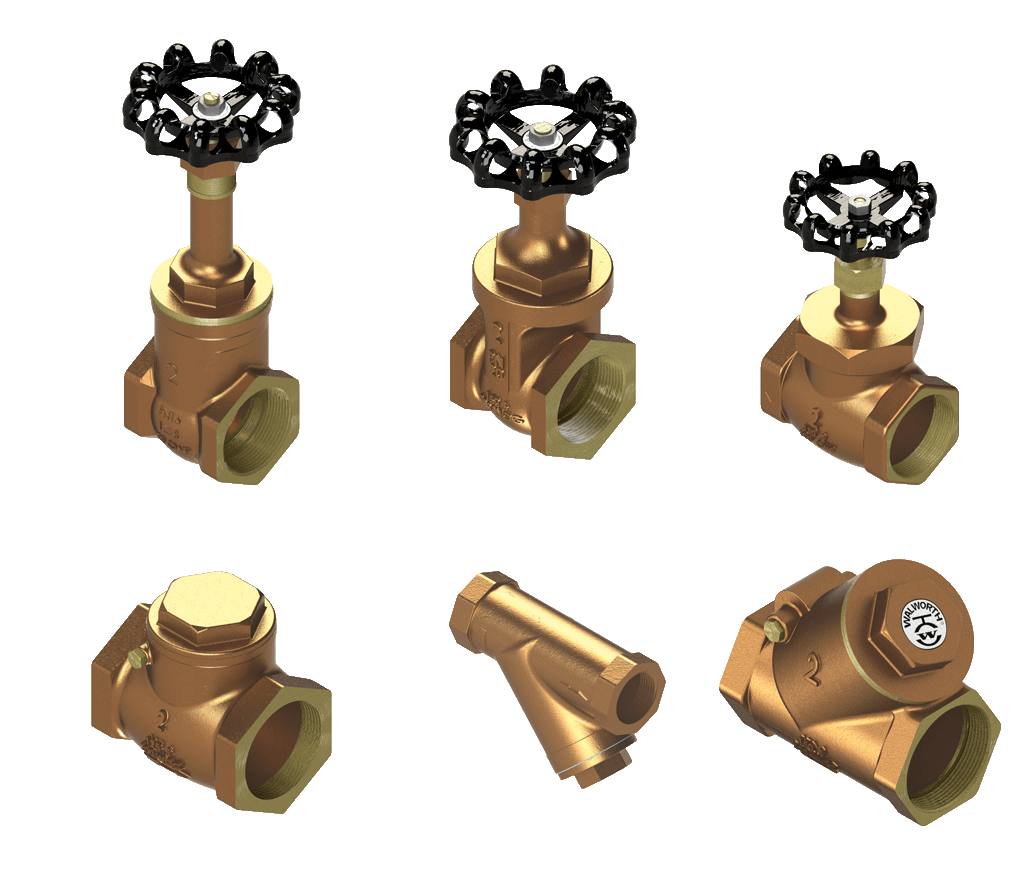

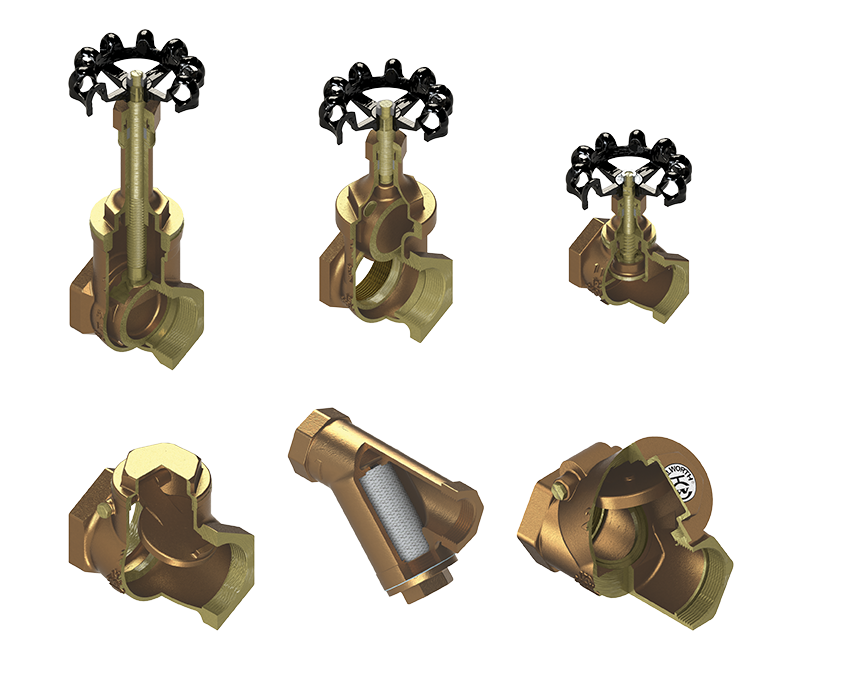

INDUSTRIAL BRONZE GATE, GLOBE AND CHECK VALVES.

- Valves used in general service applications in industrial buildings, commercial buildings and construction industry, drainage pipelines or industries where the operating temperature does not range beyond -20 to 550° F (-29 to 287° C (-20 to 550° F).

- Designed in accordance with Standard MSS-SP-80.

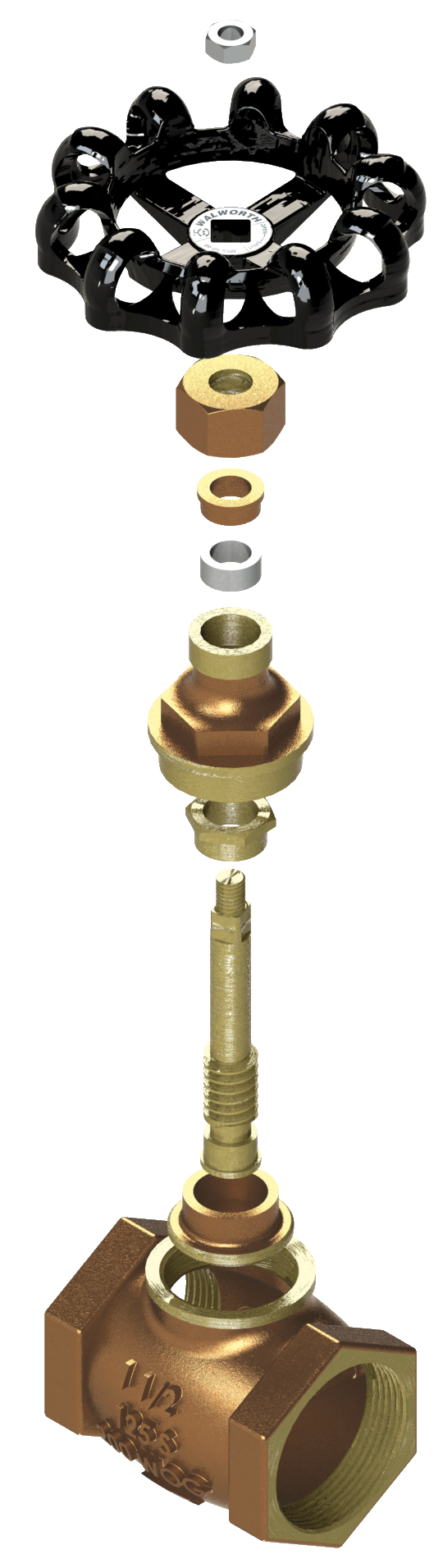

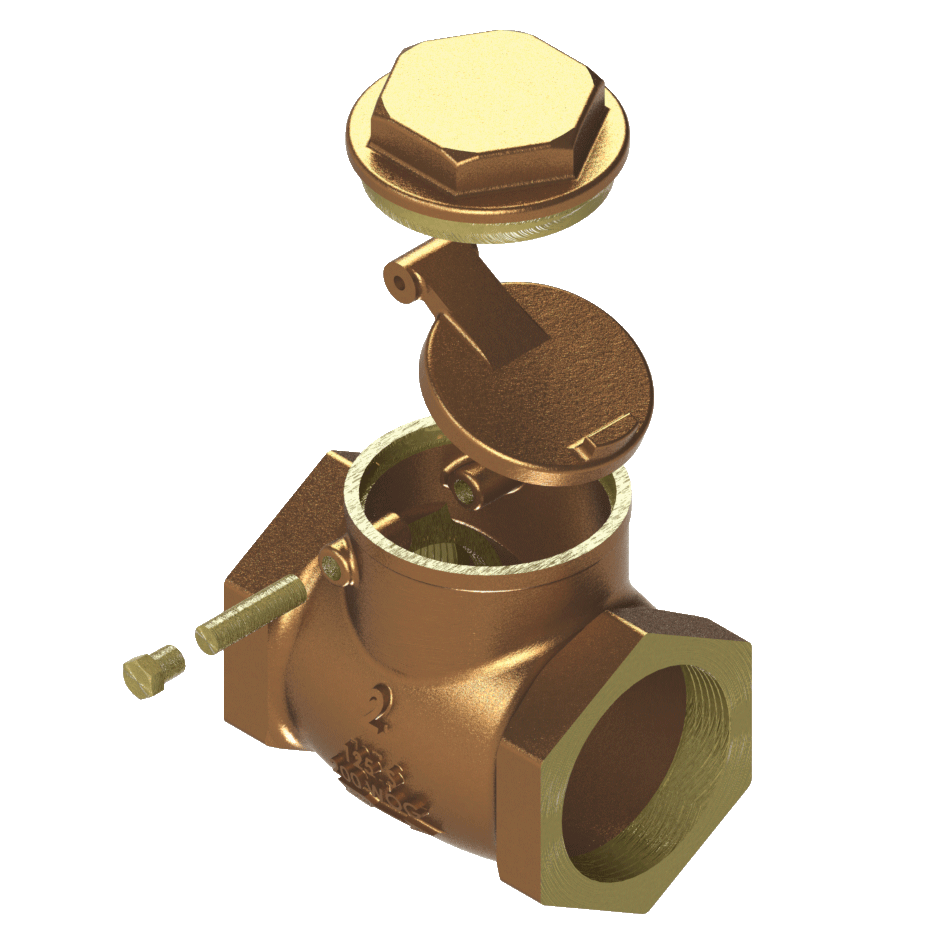

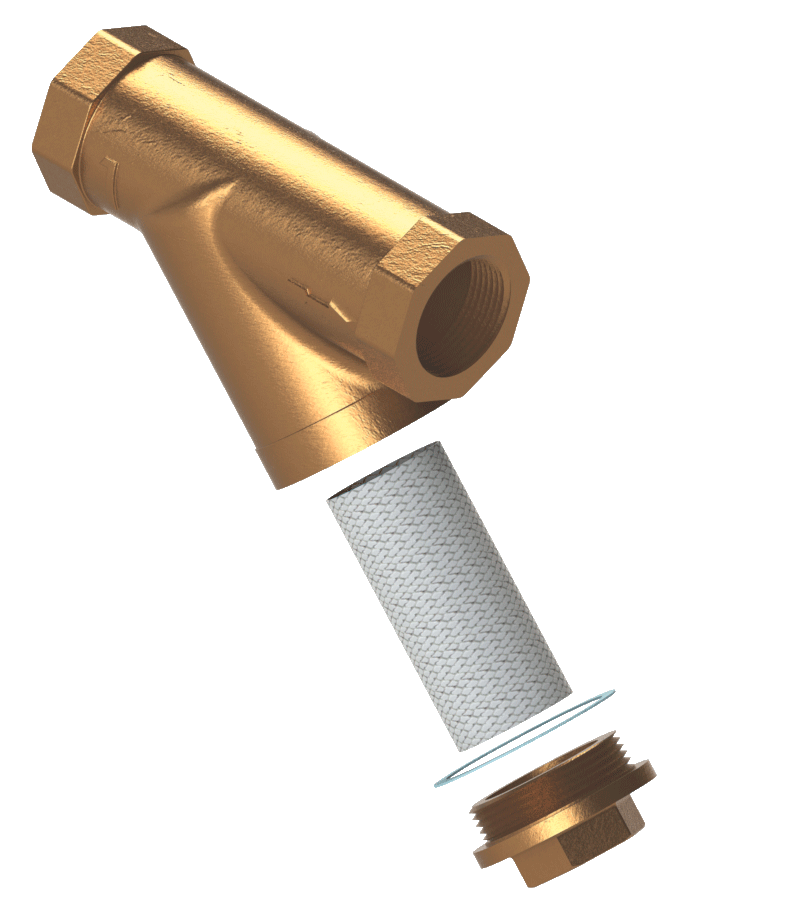

- Models:

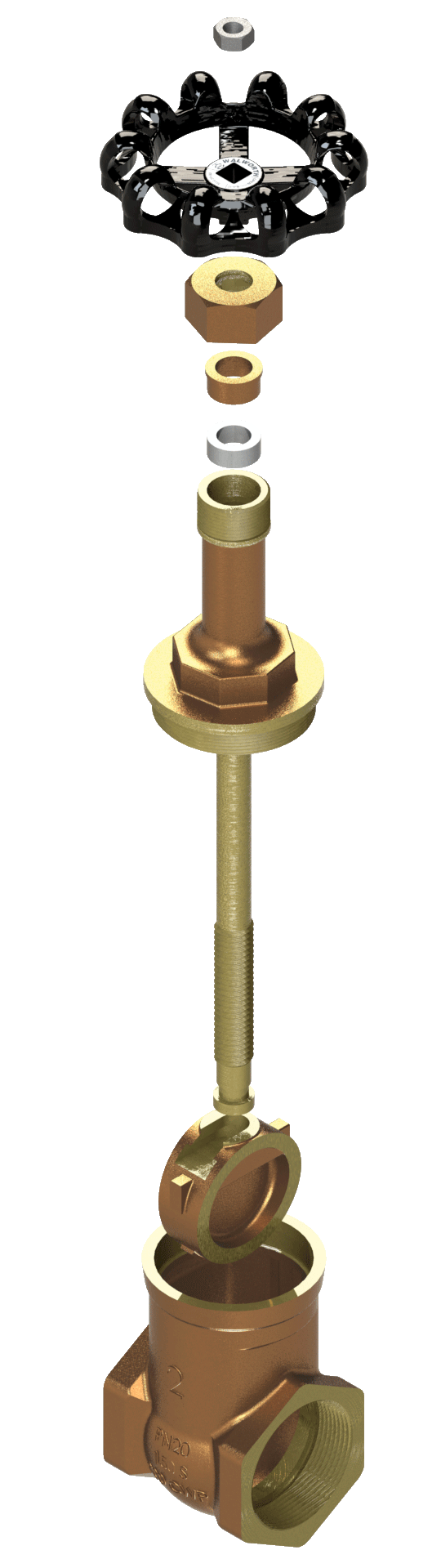

-Rising stem gate valve (ISRS).

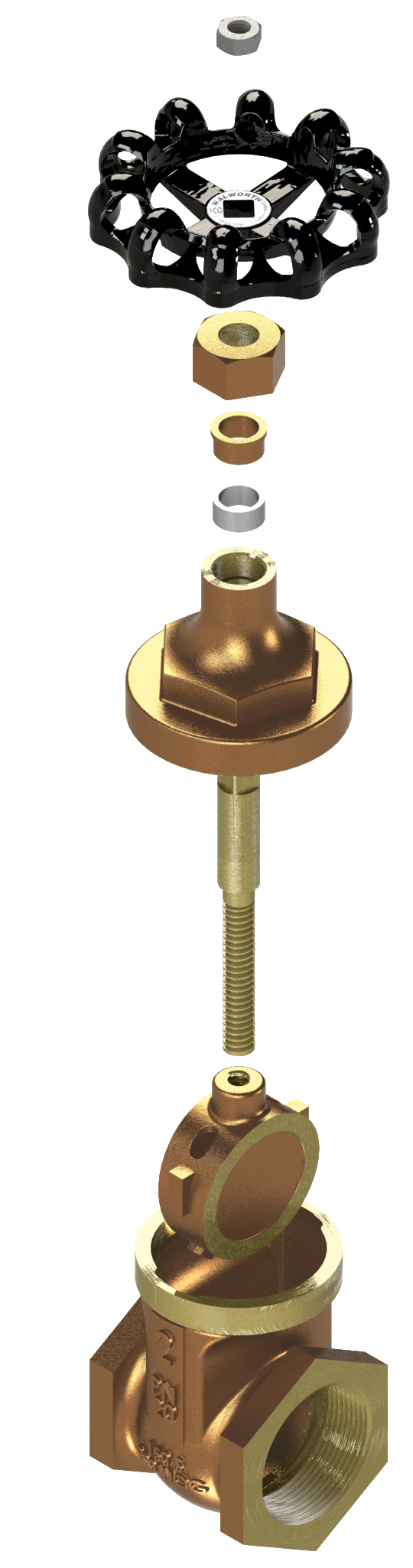

-Fixed stem gate valve (NRS).

-Rising stem globe valve (ISRS).

-Check-swing type check valve.

-Y-strainer model.